how does vapor honing work

Vapor blasting is a surface cleaning and refinishing process that restores surfaces and efficiently removes contaminants. With water serving as lubricant the pressurized slurry mixture wont scar heat or warp the original surface of the part allowing even delicate internal engine components to be vapor honed.

A Simple Introduction To Vapor Honing Issuu

Vapor honing is also known as vapor blasting aqua blasting wet blasting slurry blasting and dustless blasting.

. Instead of dry abrasive media used in sandblasting it uses a combination of water compressed air detergents with finer and gentler media to remove oxidized metal and corrosion. To remove imperfections such as heat treat scaling you add fine abrasives to the water then sprayed onto the material at great speed. Using a combination of compressed air and a flow of water borne abrasives this process gives a smooth and fine finish unlike dry blasting it leaves no damage to your parts.

Find Deals on vapor blasting kit Facein on Amazon. The key to vapor blasting is that the finish is produced through the flow of water borne abrasive giving a finer finish due to the flushing action of the water. Wet blasting can also be known as vapor blasting slurry blasting and liquid honing.

Vapor Honing often known as wet blasting is a technique used to polish precise surfaces. What is Vapor Honing Blasting. Ad Browse Discover Thousands of brands.

It is also known as wet blasting vapor honing liquid honing or dustless blasting. Vapor honing can be used on almost any surface found on a motorcycle or car including gloss plastic. Also known as wet abrasive blasting vapor blasting vapor honing dustless blasting or slurry blasting.

It cleans in areas other methods cant. On aluminum it leaves a finish that looks almost like paint. To remove imperfections such as heat treat scaling you add fine abrasives to the water then sprayed onto the material at great speed.

How does vapor honing work Tuesday March 1 2022 Edit. Its perfect for restoration work because it makes the metal surface look like new but does not remove metal like sandblasting. The vapor blasting process includes utilizing pressurized water and abrasive blast media to finish a surface.

The vapor blasting process provides the highest quality soft surface finish. Vapor Honing Technologies Lilhonda Com Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa Vapor Honing Jim S Workshop Vapor Blasting. Vapor honing does not remove metal its a finish restoration process.

It leaves a smooth satin finish and is much more gentle to the surface than dry sand or glass bead blasting. Read Customer Reviews Find Best Sellers. Vapor blasting also known as wet blasting liquid honing or dustless blasting is a process that uses pressurized water and abrasive material to remove contaminants corrosion residue or coatings from a surface.

While it can handle a wide variety of materials it gives a excellent finish aluminum zinc brass and magnesium. Vapor honing is also known as wet blasting it is safe environmentally friendly what vapor honing does is use water and fine high quality abrasives such as glass bead or ceramic powders and air all recycled and reused in our Vapor honing technologys 3630 cabinet. Fine abrasives between 2 and 400 micron are suspended in water and forced at the material at high velocity to remove impurities such as heat treat scale.

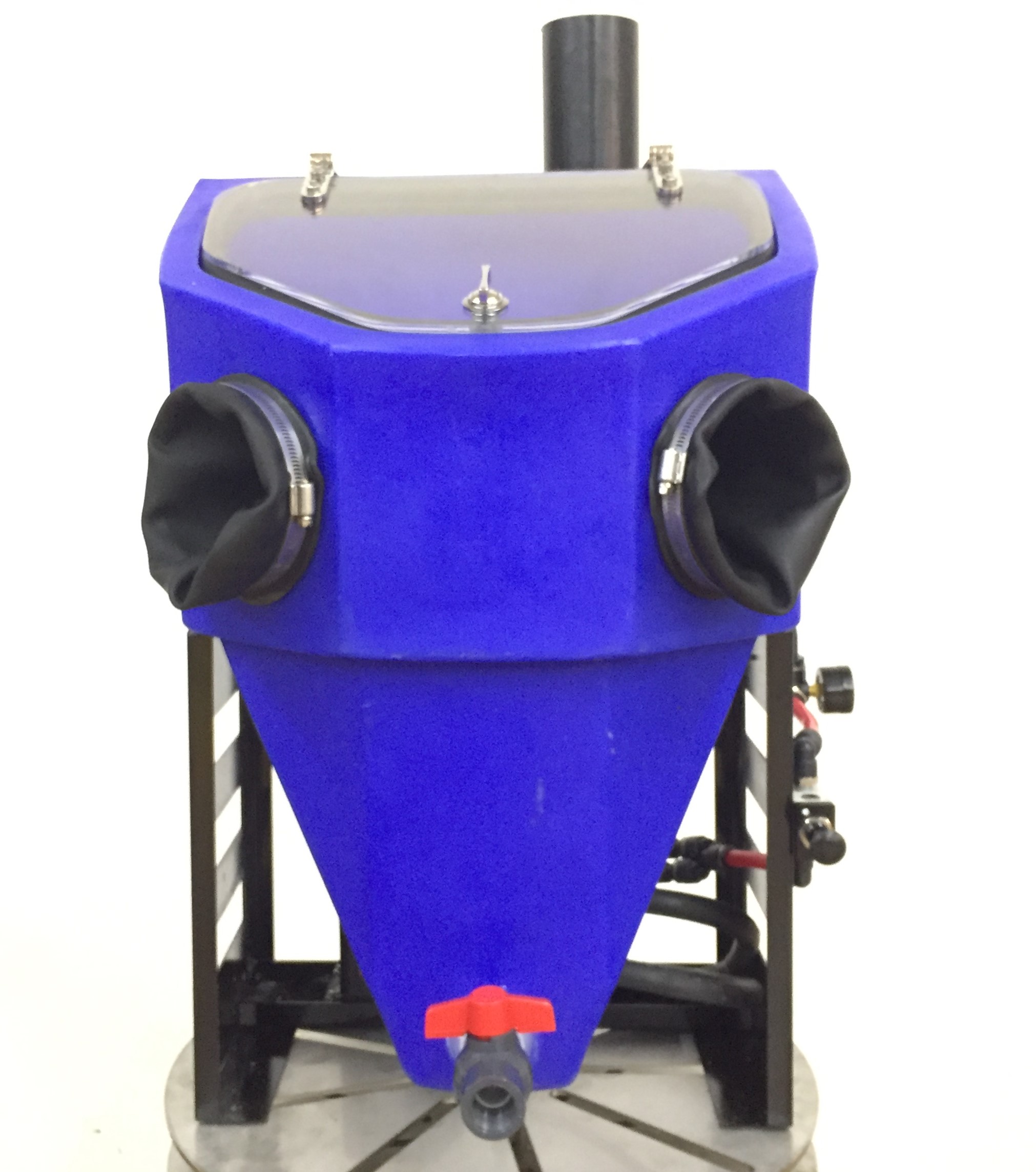

Vapor honing is also a great choice for removing very tiny scuffs and tool marks as well as for applications that need a satin-smooth. How Does It Work. A specially designed high volume pump mixes abrasive media with water.

Water abrasive and compressed air are 3 ke. Vapor honing is also an excellent option to remove very fine burrs tool marks or. Perfect for use on new components or refurbishment of any type of machinery.

Wet Blasting is an industrial process in which pressurized wet slurry is applied to a surface for various cleaning or finishing effects. Vapor honing is a wet blasting process which uses very fine glass beads and water under air pressure. Firstly the finish is achieved by the flow of water borne abrasive not by impact and secondly because it is a dust-free process.

Vapor Honing is the same process as wet blasting and vapour blasting. Vapor honing is a low pressure wet blastin g process that safely cleans restores parts leaving a nice finished surface. Vapor honing is a finishing process that utilizes water and various types of fine media to restore parts to OEM finish.

Before you start the cleaning process you need to pick the type of abrasive youll use to clean your part. Are favorite application is carbs for the finish it provides. No media is impregnated into the component nor is there any dust created by the break-up of media unlike dry blasting where the finish is produced by sheer force of media impact.

There are numerous reasons why wet blasting is becoming more favorable over dry blasting and this is primarily because of its two key features. Vapor honing also referred to as vapor blasting or wet blasting is a surface refinishing process used to clean and restore surfaces. The abrasive nature of the cleaning means the part is scrubbed clean by default.

Basically this is a technology that involves the blasting of abrasive material blast mixed with pressurized water. Vapor honing uses water and abrasive flowing across the surface to scrub away contaminates rather than directly impacting the surface damaging and removing material. Vapor Honing or wet blasting is a process utilized for precision surface finishing.

It is commonly used for cleaning aerospace parts and surfaces. The process has numerous functions for example-. How Does Vapor Honing Work.

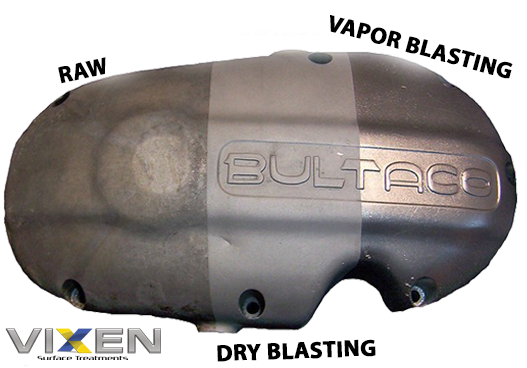

As you can see from all these names vapor honing is the wet version of dry blasting. It is the ideal for all types of materials metallic and non-metallic.

Vapor Hone 1000 Wet Blasting Equipment Blast Wash Systems

What Exactly Is Vapor Honing 5 Things You Should Know

Vapor Honing Services What Is Vapor Honing And Does It Work

What Is Vapor Blasting Answering Your Wet Blasting Faqs

Vapor Blasting Services Wet Blasting Vapor Honing Technologies

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

Vapor Blasting What It Is Costs And Shipping

Vapor Honing Technologies Lilhonda Com

Vapor Honing Services What Is Vapor Honing And Does It Work

Vapor Honing Bonehead Performance

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Vapor Honing Blasting Superfly Garage

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube